So you want to buy an affordable desktop 3D printer, but you’re overwhelmed by the options? Home 3D printing has been affordable to private users for a few years now. A quick google search will result in a plethora of affordable printers, and it’s easy to lose sight of what’s important. Let this be your guide into affordable home printing.

Let me start this off by saying this is NOT sponsored content, I will use my own 3D printers as examples, both of which are by the brand Anycubic. Both printers were bought by me through the Anycubic official Aliexpress store. Both printers cost less than $300.

Home printers – technology

As of writing this post there are 10 fundemental techniques for 3D printing, of which only 2 are used in most affordable desktop 3D printers. You’re more than welcome to read up on all 10, but I will only discuss the 2 desktop printer techniques: FDM/FFF and DLP/SLA. The image below shows an FDM printer (left), and a DLP printer (right).

FDM/FFF

FDM or FFF stand for Fused Deposit Modelling or Fused Filament Fabrication, and it is the technique used by most desktop printers. This technique heats a plastic filament (most commonly PLA), and forces this through a nozzle. The nozzle has a precision hole, and is controlled very precise by the printer. The nozzle will deposit the model, layer by layer, to create the final product.

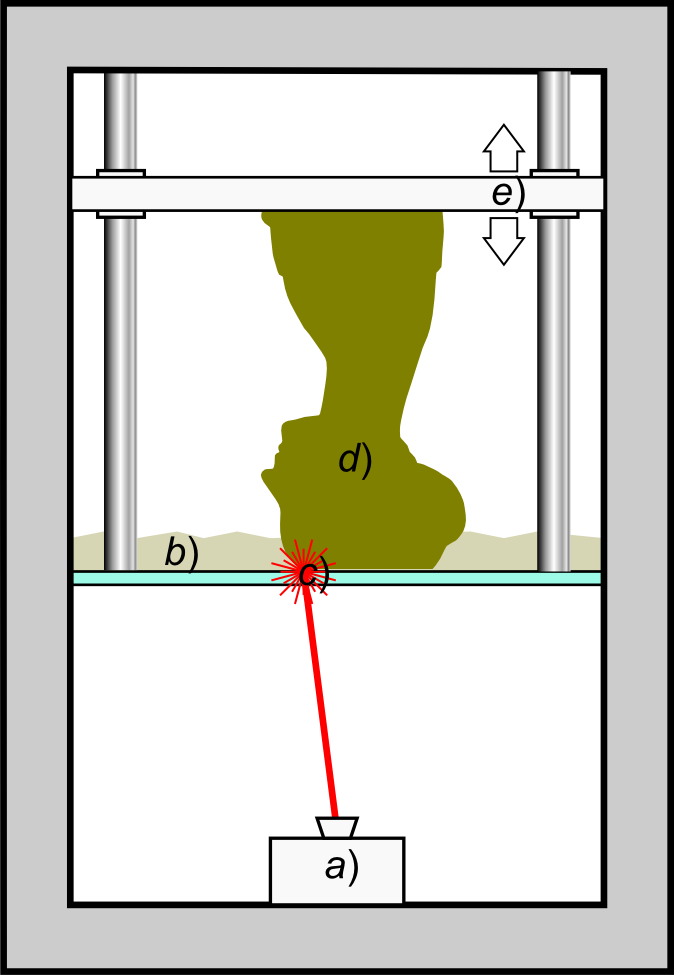

DLP/SLA

DLP stand for Digital Light Processing, and SLA stands for Stereo Lithographic Apparatus. DLP uses a UV light LCD projector to selectively cure a resin in a bath. The printer creates the model layer upon layer by lifting the model and exposing the next layer. SLA uses a similar process, but uses a precision guided laser instead of a projector.

What to consider

Choosing a printing technique is very dependent on what you want to print with it. FDM printers can use a wide range of materials, with different mechanical properties, and colors. DLP printing creates very precise models, but the material is generally more fragile.

Materials – FDM

FDM printers can use a wide range of materials, ranging from normal PLA (most commonly used), to exotic materials like carbon fibre reinforced, metal fill, or thermochromic filament. Filament printers are usually cheaper to operate than DLP, because most filaments are cheaper than the resin used for DLP printing.

FDM printing generally yields models that have decent impact resistance and can be used for mechanical applications (brackets, clamps, etc.). When creating models for mechanical applications, take care of the printing orientation. FDM prints can take more compression and strain in the XY directions. The printer builds the models layer by layer, and the adhesion between layers is usually less strong than the XY direction.

Materials – DLP

The resins used in DLP printing come in only 3 flavors as of writing. Normal resin, engineering resin, and dental resin. Normal resin creates very precise models, but the models are quite brittle. Engineering resin has much better mechanical properties, but these greatly vary per brand. Engineering resins also need a longer layer to layer cure time, which slightly influences the precision.

Precision

Below is a comparison of my own FDM and DLP printer, the yellow model is FDM, the red is DLP. The FDM printer has a a precision of X/Y 0.0125mm and Z 0.002mm. The DLP has a resolution of X/Y 0.0047mm and Z 0.00125 mm. The difference is clearly visible in the model below.

Build size

Another thing to consider is the maximum build size for your printer. FDM printers have larger build volumes than DLP printers. My FDM printer has a build volume of lxbxh 210x210x205 mm. My DLP printer can only print 115x65x155 mm.

How to choose

So, how to choose? This strongly depends on your needs. For large prints, mechanical prints, and/or the lowest operating costs, FDM is the way to go. For high precision (or dental models), DLP is the better choice.

If you want to know more about either printing technique, reach out in the comments or email me.

You’re doing a excellent job Ma,,Keep it up.

Best regards,

Thompson Schneider

This is article you shared great informationIi have read it thanks for giving such a excellent Blog.

Best regards,

Boswell Duke